KyronMAX® Structural Thermoplastic Compounds Offer Expanded Resin Formulations

Strongest moldable polymers available for metal replacement applications

The world’s strongest injection moldable product line of structural thermoplastic materials using advanced carbon fiber technology adds new formulas reaching 60,000 psi tensile strength.

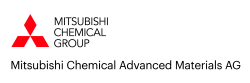

Tensile Strength Comparison Using the Same Fiber Loading

KyronMAX® compounds exhibit much higher mechanical strength, than conventional glass and carbon filled systems, at the same fiber percentage loadings. The increased mechanical performance, allows the use of lower filler loadings, increasing the material’s strain, which allows the part to yield and not fracture.

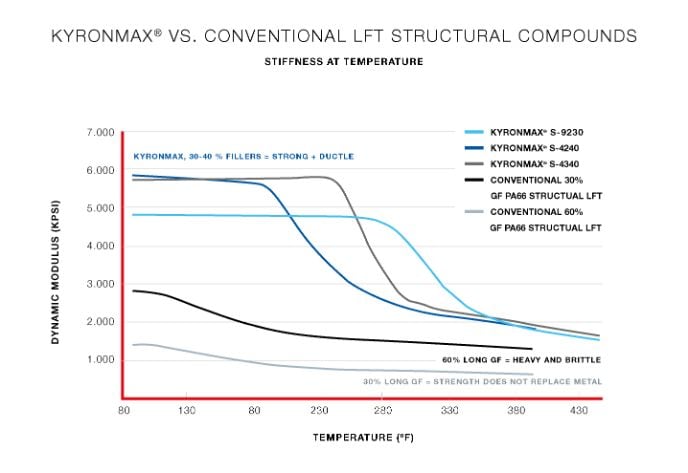

KyronMAX® vs Conventional LFT Structural Compounds Stiffness at Temperature

This standard Dynamic Mechanical Analysis (DMA) summary compares material stiffness over an elevated temperature range. As displayed, conventional glass and carbon filled Nylon compounds lose mechanical performance very quickly when exposed to even low elevated temperatures. In comparison, the KyronMAX products demonstrate excellent property retention even in the harshest of temperature regions.

Contact Us Now!

Fill in your details and one of our expert teams will get back to you as soon as possible.

I have read, understood, and accept the privacy notice and terms of use of Mitsubishi Chemical Advanced Materials AG

I agree to receive informative updates and offers about and services via e-mail from Mitsubishi Chemical Advanced Materials AG and its affiliates. I'm aware of my right to revoke my consent and its details at any time through the preference center.