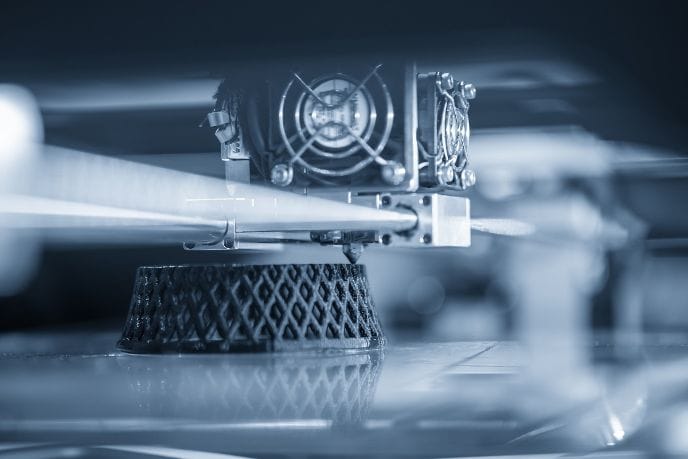

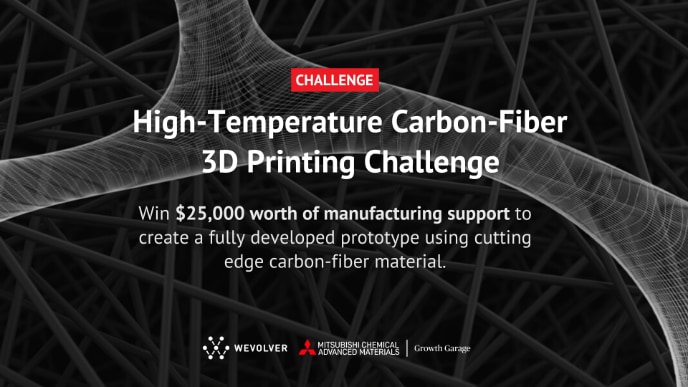

Sorting Wheel

How does the relative production cost compare to CNC Machining and 3D Printing (FFF, Fused Filament Fabrication) of a sorting wheel like?

Learn about how SPRINT (Soluble Printed Injection Tooling) could facilitate smooth scaling of your product in this case study.