Consolidate your supply chain

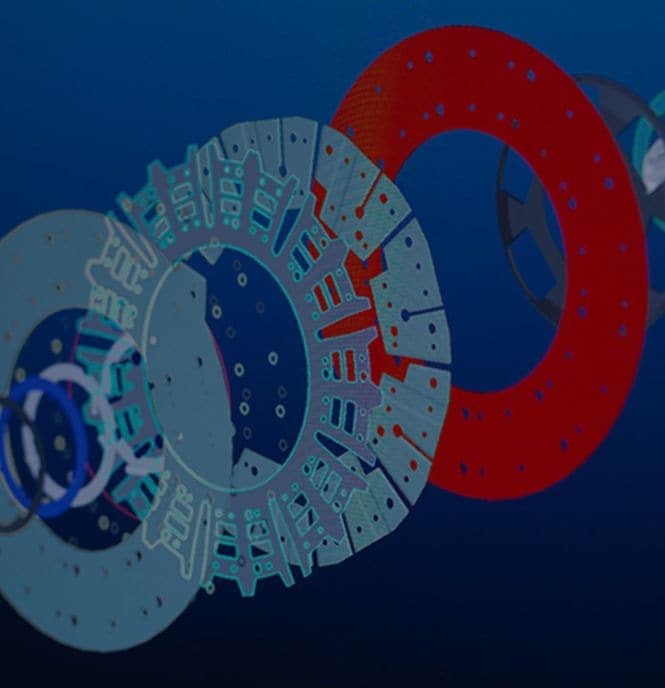

Our global, vertically integrated structure, network of regional facilities and backward integrated value chain, means greater flexibility in your supply chain from materials purchase to prototyping and even part production.